EEC Presents an Outstanding Opportunity to Grow Business!

The economic recovery of Thailand will be fueled in large part by investment in the targeted S-curve and the new S-Curve industries within the country's Eastern Economic Corridor (EEC) - the government's flagship project aiming to transform the Thai economy by keeping pace with technological changes, embracing future technologies, and moving towards Industry 4.0. Meanwhile, transport and digital infrastructure are being upgraded in Chachoengsao, Chonburi and Rayong, to boost investment and foster sustainable economic growth. The latest EEC investment plan for the period 2022-2026 is now standing at a combined investment value of 2.2 trillion baht, with a focus on innovations and advanced technologies.

For many years, Thailand achieved the most installations of industrial robots in ASEAN and as the second-largest Automation & Robotic market in the region after Singapore. The advent of smart factories - the intersection of smart devices, industrial robotics, data centers, cloud services, 5G, AI, IoT, remote sensors & controllers and advanced machinery - is central to transform the industrial sector into a smart engine of development by using digital manufacturing that is driving industry 4.0 and is taking place in Thailand, especially in the EEC.

Today's rising reliance on the high-speed 5G connection, AI applications, and IOT provides manufacturing with high accuracy and minimal error. With these technologies being used in major factories across the EEC, smart solutions for predictive maintenance are also critical in order to minimize or prevent the breakdown of production equipment. An unscheduled major repair on a machine could shut down an entire production line and the consequences can be costly. Predictive analysis and data collection with machine learning and AI can reduce expensive downtime and maintenance while improving the overall effectiveness of the machines and equipment.

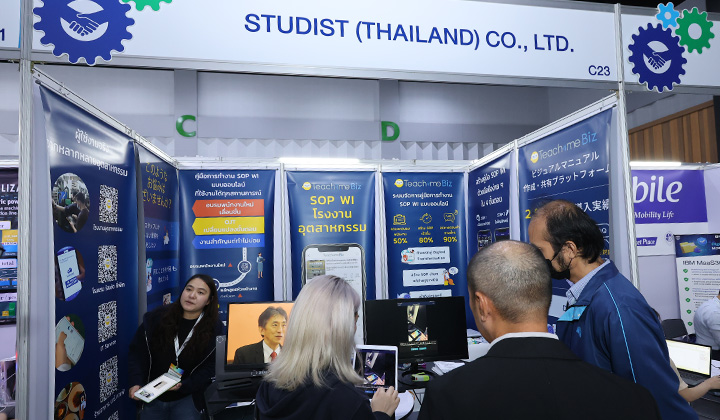

With these industrial developments in the EEC, MiRA 2023 will present excellent business opportunities for machinery makers to connect and do business with some key decision makers from across the EEC - An opportunity not to be missed!